The most reusable warehouse tag available is a magnetic rack label. They can:

Most magnetic signs are used for shelf and rack location labeling as well as temporary information placards. As such, we use our specialist software to design and create the most effective layouts for each use.

Labels can also be produced in any size, so from the very small to the very large, ASG Services is able to design for every need.

Along with as mono and full color graphic print, our magnetic signs are produced with barcodes, alpha, numeric and alphanumeric content for use with warehouse management systems in distribution centers.

Blank Magnetic Labels |

Pre-Printed Labels |

|---|---|

|

|

Perforated Magnetic Rolls |

|---|

|

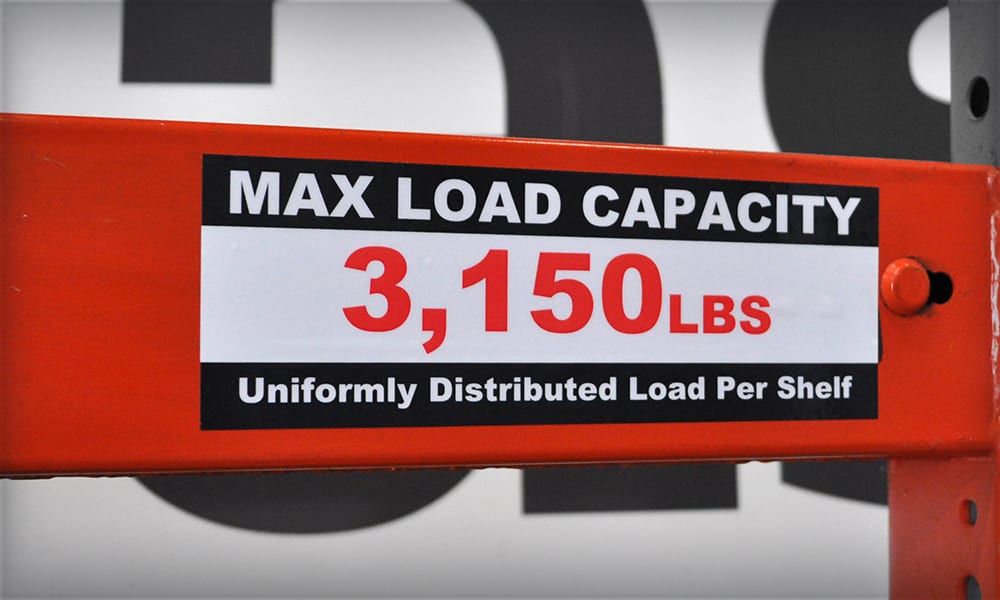

At ASG Services, we also specialize in the production of capability load labels, designed to present the safe loading limits of rack and shelf structures in storage facilities.

Although the loading capacities rarely change, some customers move and reorganize their layouts to suite product stored, therefore the labels may need to be changed. Magnetic load labels are ideal for this situation.

To find out more, visit our load capacity label page.

ASG Services produce more rack location labels than any other product and yet every one of them is different from the next. This combined with years of product development means we have a huge range of options so the rack labels you order a best suited to their needs.

Magnetic rack labels have always been a popular option with customers. Our custom approach with layouts, size, full color print, quality and magnetic strength and ability to produce low volume orders makes us the ideal supplier to many.

To find out more, visit our pallet rack label page.

Serving a similar purpose to pallet location labels, shelf tags are generally moved more frequently, particularly in production facilities.

They are moved to accommodate larger volumes of products, changes in product size, and to incorporate new images.

Our quality checks during the production process and strong communications between our team and the customer ensure shelf labeling projects are always a success with some in the thousands of labels, others in the hundreds of thousands.

To find out more, visit our shelf labels page.

Using the latest print technology, we are able to produce vivid graphic displays as well as high definition intricate designs which perform to the high demands of industrial use, making them compatible with any barcode scanner.

Magnetic rack labels are typically produced from sheeted material which is supplied in 5 standard thicknesses, .015”, .020”, .030”, .045”, and .060”. Each thickness offers varying levels of pull force, from 6.2 to 11.8 pounds per feet. This is often important for industrial use as it helps prevent the magnetic signs from being knocked off the rack beam or shelf edge.

Custom magnetic labels give customers confidence in the product, versatility and installation as misplaced labels are easy to rectify.

Barcodes can be either printed direct to or applied to the magnetized material following the print process. ASG Services recommend the use of polyester and high grade vinyl for the barcode material to minimize barcode disturbance.

As a result of the magnetic tag production process, labels are typically supplied as singles, but thanks to cutting technology, they can also be supplied on rolls and as scored sheets. To help protect the print face, ASG can apply a laminate coating, which is very useful with movable ID products as the face is susceptible to damage during relocation.

Customers looking to create their own can contact us about pre-cut magnetic strips, we can provide these in a variety of sizes.

Organizations implementing large projects using magnetic signs benefit from ASG Services fully managed installation teams. Trained and insured to work on any customer site, they have the attention to detail and knowledge of numbering sequences to provide a successful warehouse labeling installation in record time.

In preparation for our projects, we are able to provide support services in the location data handling, product design and install schedule planning.

For more information, read about ASG Services storage location data handling, warehouse label designs and rack label installation services. Also, please feel free to contact us direct, we’re always happy to help and demonstrate how we can be a valued partner to you and your project. Call us on +1 (877) 447-9798.

Any size you need. Every order we fulfill is customized, so you can specify a size, and we will provide the product as needed.

We are not a graphic design studio but we are capable of designing any label layout required. Variable content data and multi field options are possible, our only restriction on the number of barcodes and characters is the size of label you request. We will always suggest a size which best suits your requirements.

It is true that location labels do not need color to work, but we recommend color to help the users identify key location information quicker. Color is know to improve speed of identification, to read more visit our warehouse color coding article.

Color identification may be used as a level indicator on racking where each level in a rack bay has a unique color, so as the operative looks up, they can distinguish the level quickly and shorten their reading time. It can also be used as a zone identifier particularly with bulk storage floor locations, aisle groups in racking and shelving is another.

Another well represented use of color is with warehouse striping for staging lanes, bulk storage bays and walkways. See our warehouse striping page for more information.

Some customers use it for aesthetics for their in-house branding.

Quantities, sizes, location, aisle widths, beam heights, building operation status, start date and a thorough conversation so we understand exactly what you are hoping to receive from us and to achieve from using a company like ASG Services.

If you are not able to generate a location file from your warehouse management system, we recommend you use a spreadsheet to help build your own. Spreadsheets allow you to use columns to separate the location sub references, and the rows to quickly expand the number of derivates per run. These columns of data can then be combined to create the barcode data and separately to create the readable elements with separators so operatives can read the rack and shelf location names easily.

Read more on how to build a warehouse location data file.

Please call us on (877) 447-9798 to discuss you needs, we're happy to help and to answer any questions you might have.

Send us an email with the questions you have or images of labels you want to replace and we'll provide all the information you might need.

Choose from a small selection of sizes and designs and order online from ASG's online store.

Label Holders

Label Holders

Location labeling becomes more versatile with warehouse label holders, shelf edges and rack beam faces remain free from adhesive build, paper-adhesive, residue and handwritten references, created because adhesive labels no longer stick.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now