As the leading manufacturer and project installation specialists throughout the US, we understand the challenges faced by people who undertake rack labeling projects. In many cases, it’s the first time they have done anything like it and particularly in scale.

Our intention with the information here is to help you. We add value to rack labeling projects every day, and we know the help we can give you early in the process can help save your valuable time and overall costs. We hope to explain some of the basic elements of labeling pallet racking and are always available to speak if need to call.

Rack labels by virtue of their name, are labels placed on industrial pallet racking and shelving. Where they are placed on those structures determines the names given to them, their design, content type and layouts.

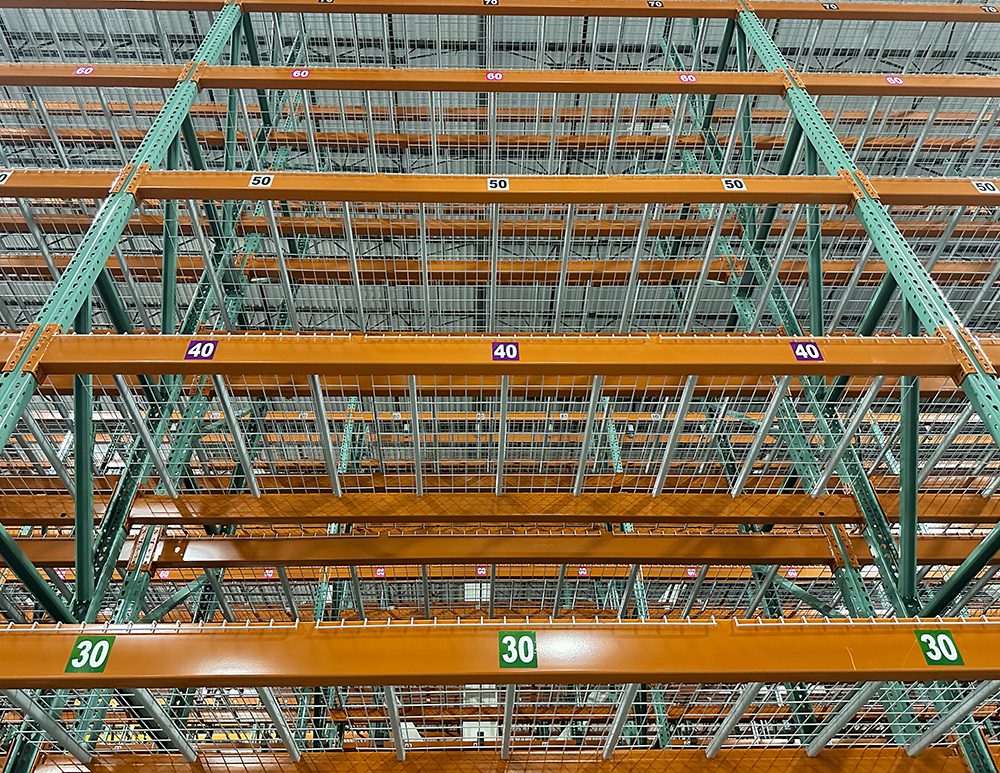

Labels placed on the rack beam face, or shelf edge are those most seen in distribution centers and retail. They provide a reference for the location naming convention, immediately above or below the label.

The rack frame legs are used far more in distribution centers. The label is placed on the vertical section, and often becomes a vertically stacked design, providing location references for positions to the left or right high up. This makes it easier for operators to read the characters and scan the barcodes from the floor.

A label which provides location reference to the lowest level storage position, at the ‘base’ of a pallet rack bay.

Simple layout with readable characters that describe the location, often with the aisle name, bay identifier, level, and position number along the shelf. Color is adopted by many as an additional coding characteristic.

Aligning with the storage location on the base beam is most common. There is often a need for additional labels and placards on the base beam, however the location name label is the priority. Being the easiest to identify and use is essential for operational efficiency.

A pallet rack label which references the lowest and first level positions on one label, which is placed on the beam between the two levels and designed with arrows or reference to the locations represented.

Two sets of data require careful layout to avoid cross scanning and miss-reading, however size is limited by the beam height, and in more recent times, by the cascading wire decks. Color is an excellent way to overcome data separation and is the initiator of higher-level color coding. As the label sits between two locations, the lower location reference goes below the higher, although some like to place them next to each other, one left the other right.

Being on the beam between the base location and first level, means they often sit centrally to the pallet position and vertically on the beam. Occasionally, where step labels are used, the split base would be off center to accommodate the step label, so combined the together sit central to the pallet stack going up. This can be seen in the multi-level configuration image below.

A rack label that provides location references for several positions above, making the information easier to read and the barcodes easier to scan. In addition, they reduce material used and installation costs.

These are one of the most complex variable data labels used for rack labeling. Often six or more location names and barcodes are combined and presented to minimize cross scanning. Label size is dictated by real estate on the beam face, and so color coding becomes a significant advantage.

Multi-level rack labels are often placed on the highest reachable beam from the floor. In standard selective rack configurations, this is usually the first level beam, however in pick aisles, the beam used is often six feet from the floor and beams below are in shelf configuration. They are placed central to the pallet stack and when combined with split base labels, they are off set so together they are central.

Like a base label, the upper-level beam label provides the location reference for one location, usually immediately above, or below, however these labels are on the higher-level beams high up.

Characters which represent the location naming convention, a barcode and possibly an arrow for directional instruction are the key components of the design layout. Those using color-by-level will adopt a flood color or colored shape to increase identification. Their size varies based on usage need. Small labels are enough where pickers go up to level, however where scanning is from the floor, the label needs to be larger, and the material may change to being reflective which allows for scanning over twenty feet.

Placement is almost always central to the pallet position on the beam face as there are rarely any other labels to be applied to the higher beam levels. Operations scanning from the ground may apply the label to wrap under the beam, so the barcode presents toward the floor.

A simple label that displays a number, letter, color, or shape, relative to the beam level it references. Often used where upright labels are applied to the frame legs and upper beam labels are not used. Also used on shelving for faster level referencing.

Small with high contrasting colors to simply present the level reference. Occasionally, characters are omitted with just a color used to show level differentiation, however we always recommend characters to help those with vision impairments.

Central on the beam, or on the rack frame, or in the example shown, a label centrally placed per pallet position.

A label that provides references for pallet positions on racking which are high up, enabling the operative to read and scan the label from the ground. Placed on the rack frame leg these labels are common in wide aisle rack configurations.

Along with multi-level beam labels, upright location labels are the most complex rack label. They hold multiple location positions per label. Owing to their position on the storage structure, their layout is in a vertical stack. Adding color or separation bars to the barcode and character layout helps present the references more effectively. The width should always fall inside the width of the frame leg, so it is not knocked off.

Centrally located on the frame leg, and at a reachable height from the floor are the key positioning considerations. Next is the number of them you will use. There may be two, one for locations on the right, and one for the left, however it may go to three depending on the number of slots per beam level.

Durability is essential when selecting label materials for industrial use, and there is little that comes close to the durability and cost effectiveness of polyester. It is the bedrock of rack label substrate owing to its stable nature. Barcodes printed on polyester will perform as well in 25 years, as they do tomorrow.

We combine layers of polyester for coated labels, laminated for extra print protection and durability.

Synthetic core forms the print base of our plastic labels, used for upright rack labels. Labels placed on rack frames are prone to vandalism, through puncturing due to the holes in the frame. Not being able to scan a barcode because someone has put a hole in the barcode can render your facility in limp mode. You will not have that problem with our plastic labels.

Many materials suffer over time, from expansion, retraction, and fragility, so it is important to consider your labeling project as an investment, cheap doesn’t always mean good.

High resolution digital print technologies achieve the best barcode verification quality, as well as the dynamic color sets you might choose. It also works best when images are integrated into the design of a label, or brand identity is followed throughout your facility.

These vary based on the environment and surface which rack labels will be applied to and in. An example of those provided by ASG Services are:

And

There is a lot of information to work through here, but if you have ready to talk, or if you have ideas and are ready to discuss your project in more depth, we will be more than happy to hear from you. Go to our contact us page.

We can't cover everything but we are happy to talk to answer any questions you have. Please contact us on (877) 447-9798.

If you have images, ideas or location data that you want to use to start your rack labeling project, send them to us on email and we will contact you to continue the conversation.

Send us an email with a list of samples you would like to see. We know it can make life easier to see them on your own racks.

Color Coding Can Improve Warehouse Efficiency

Color Coding Can Improve Warehouse Efficiency

Warehouse space and locations are typically identified with some kind on name plate, be it a rack labels, aisle signs, barcode hanging signs or floor labels. Whichever are used, they generally have a unique numbering system for that building, area or storage type, which are unique.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now